Masonry is a construction method where materials like bricks, stone blocks, or concrete blocks are stacked on top of each other to create structures or walls. Masons use mortar, an adhesive paste, to fill gaps and bind the materials together. It’s commonly used for building foundations, walls, columns, and similar structural components – but masonry projects can include walkways, walls, arches, beams, and fireplaces. To ensure durability and integrity, build masonry structures on stable ground, often with concrete foundations, for added security.

The advantage of masonry lies in its ability to perform various functions in load-bearing structures, such as supporting loads, dividing space, providing insulation, and offering protection from fire and weather. These functions would typically need separate elements in framed structures. Look over here, we got the cement board stucco system.

Materials Used for Masonry

Brick has a rich history and remains a top choice for masonry construction. It’s a classic building material made from a blend of clay and sand, usually sporting a red or brown hue and a rectangular shape. It’s commonly used to construct building exteriors and the walls around fireplaces, thanks to its affordability and widespread availability. And the reason why it can withstand the big bad wolf’s huffing and puffing is its excellent durability. Under ideal conditions, it can last for up to 500 years.

Many homeowners love the low-maintenance charm of a brick-and-stone exterior. You’ll often find bricks in places like fireplaces and chimneys, even if the rest of your house is made of different materials like concrete or wood. However, keep in mind that bricks are hefty and can place significant stress on foundations, potentially leading to costly repairs.

Builders stack bricks on top of each other in various patterns, depending on the desired structure and style, and secure them using mortar. Over time, the mortar sets and hardens, creating a robust and weather-resistant design that can withstand both the elements and fire better than many other materials. This makes bricks a cost-effective choice for masonry construction, and their easy transportation to and from construction sites adds to their appeal.

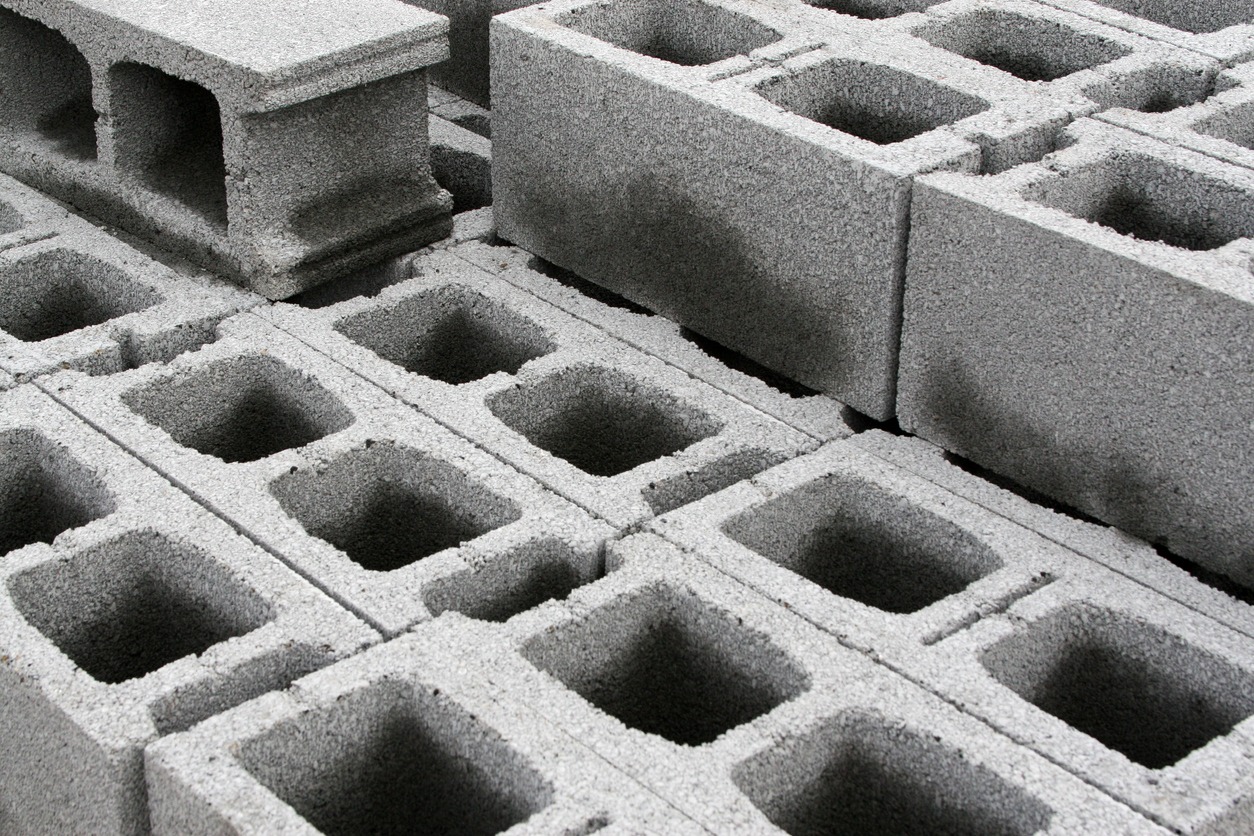

Cinder Blocks

Cinder blocks are one of the most widely used and crucial materials in masonry. These blocks are shaped like rectangles and are crafted from a mix of cement, gravel, sand, and water. They are similar to concrete blocks but are made with a lower-strength concrete mix that includes fly ash or cinder as an aggregate. They are often used for non-load-bearing walls, fences, and retaining walls.

People appreciate cinder blocks for their impressive durability and cost-effectiveness. They’re incredibly sturdy, standing up to fires, harsh weather, and the test of time. Plus, they’re environmentally friendly since they can be recycled.

However, it’s important to note that cinder blocks aren’t great at insulating against temperature or sound. To keep things cozy and quiet, you may need to add insulation inside or outside your cinder block walls.

Concrete

Concrete has been a cornerstone of construction since Roman times, and it’s still going strong for a good reason—it’s incredibly durable. You can spot its enduring legacy in ancient statues, coliseums, and iconic columns that have stood the test of time for thousands of years.

In today’s world, concrete remains a vital part of our homes. It forms the strong foundation for most new houses in America and can often be found in your driveway and sidewalk. If you’re looking to add some elegance to your backyard, stamped concrete patios are a great option—they’re both stylish and relatively easy to install.

As for its composition, concrete is a blend of cement, sand, and gravel. When applied to a surface and mixed with water, it becomes a robust material that can handle foot traffic with ease. Masons work diligently to ensure a smooth finish and prevent cracks in the concrete.

It’s indispensable for structural work, such as pouring slabs. With concrete, you have options, such as:

Normal Strength Concrete: Normal strength concrete is a common type used in masonry applications. It typically has a compressive strength ranging from 2,500 to 5,000 psi (pounds per square inch). This type of concrete is suitable for general-purpose masonry, such as concrete block walls and some structural applications.

High-Strength Concrete: High-strength concrete has a significantly higher compressive strength than normal-strength concrete, typically exceeding 6,000 psi. It is used in masonry applications where exceptional strength is required, such as in high-rise buildings, bridge piers, and other similar structural elements.

Lightweight Concrete: Lightweight concrete is engineered to have a lower density than normal concrete. It is often used in masonry for its reduced weight, which can be advantageous in applications like precast concrete blocks, where ease of handling and transportation is important.

Precast Concrete: Precast concrete blocks are substantial and dense, making wall construction a speedy process. These blocks also provide excellent insulation.

Pervious Concrete: Pervious concrete, also known as porous or permeable concrete, is designed to allow water to pass through it. It is used in masonry applications where drainage and stormwater management are important, such as parking lots, driveways, and walkways.

Translucent Concrete: Translucent, or light-transmitting concrete, adds optical fibers to the mix, creating captivating visual patterns on both sides of the material. This type of concrete can be a fantastic choice for masons working on commercial properties or clients who want to add a unique visual element to their space, especially on walls.

Shotcrete: Shotcrete is a type of concrete that is pneumatically projected or sprayed onto a surface. It is commonly used for creating structural walls, tunnels, and other masonry applications where a rapid application method is needed.

Fiber-Reinforced Concrete: Fiber-reinforced concrete incorporates various types of fibers (such as steel, synthetic, or natural fibers) to enhance its tensile strength, durability, and crack resistance. It can be used in masonry for added structural integrity and durability.

Self-Consolidating Concrete (SCC): SCC is a highly flowable concrete mix that requires little or no vibration during placement. It is often used in masonry applications where achieving complex shapes and ensuring full compaction in tight spaces are essential.

Ready-Mix Concrete: Ready-mix concrete is a convenient pre-made blend of Portland cement, sand, and gravel. All it needs is water, and it’ll harden and cure. It’s a handy choice for building fence posts or supporting decks.

Insulating Concrete Form (ICF): Insulating concrete forms (ICFs) are specialized structures that reinforce concrete, helping it stay in place and maintain its stability while retaining heat. Builders often use ICF masonry for walls, ceilings, and floors, making it a common choice for residential properties.

Cement

Cement is a material that hardens when it’s exposed to water or air. When mixed with fine sand, it becomes mortar, and when combined with gravel, it turns into concrete. It’s essential to be cautious when handling cement as it can harm your skin, and it’s sensitive to adverse weather conditions.

This is the most widely used type of cement is Portland cement, and it is the basic ingredient in concrete. It comes in different grades, each with varying properties suitable for different applications.

Portland cement is a blend of lime, silica, alumina, iron, and gypsum. You can find it in 50 and 100-pound bags. It’s important to note that cement isn’t the same as concrete; concrete includes aggregate, while cement does not.

Block Masonry

There are different types of blocks used in masonry, including:

Solid Concrete Block Masonry: In this type, solid concrete blocks are stacked and bonded together with mortar. Solid concrete blocks are gaining popularity because they offer excellent stability, and it is often used in load-bearing walls and structural applications.

Hollow Concrete Block Masonry: Hollow concrete blocks have cavities or voids, which reduce the overall weight of the structure and the number of joints required. This type is known for its insulation properties and is used in both load-bearing and non-load-bearing walls.

AAC (Autoclaved Aerated Concrete) Block Masonry: AAC blocks, made from steam-cured cellular (aerated) concrete, are lightweight and have excellent insulation properties. They are made from sand, cement, lime, and aluminum powder. They come in blocks and large pre-fabricated units for various building applications, including floors, walls, and roofs. AAC block masonry is eco-friendly and used in residential and commercial construction. The larger these blocks, the quicker the masonry work progresses.

Glass Blocks: Glass block masonry involves stacking slightly opaque glass squares or rectangles to create windows, walls, or doors. Glass blocks are commonly used as decorative elements to complement the overall tile design. They can also be frosted to allow in natural sunlight while still providing some privacy. While they add visual interest to a space, it’s important to note that they can’t bear any structural loads.

Stucco

Stucco is a cement-based product that forms a thin layer over your home’s existing woodwork and masonry. It’s easy to paint and offers the advantage of being moldable and textured. If you desire the appearance of brick without committing to deep reds and browns, stucco allows you to create a faux brick look.

Similar to brick, stucco is highly resistant to damage, fire, and wind, making it very durable. However, it does come with concerns about moisture buildup, particularly on downward slopes. Another downside is that working with stucco can get quite messy.

Rammed Earth

Rammed earth is a blend of various materials, mainly gravel, stone, and clay, commonly employed in crafting walls, floors, and building foundations. It’s an ancient technique that is still used in sustainable and energy-efficient building projects. Its eco-friendly attributes made it a preferred choice among builders, especially as an alternative to concrete.

Adobe

Adobe is a traditional and sustainable masonry material that has been used for centuries, primarily in arid and semi-arid regions like North and South America, the Middle East, and North Africa. It is composed of natural raw materials, including clay-rich soil, sand, straw, and sometimes small stones. Adobe Construction is renowned for its simplicity, thermal performance, and sustainability. Here is an expanded overview of adobe as a masonry material:

Adobe construction typically involves mixing the raw materials, forming them into blocks or bricks, and allowing them to dry in the sun. The blocks are then stacked and bound together using adobe mortar, which is made from the same raw materials but with a higher clay content.

Gravel

Gravel is a mixture of sand and gravel deposits available in various sizes. It’s used to create lightweight or coarse concrete. When choosing gravel size, consider the level of resistance you aim to achieve for your project.

Sand

Sand often goes unnoticed, but it deserves attention because it plays a significant role in construction. It affects the strength, bond, workability, shrinkage, and appearance of mortar.

Coarse sand is used for mortar sealant, while both coarse and fine sands are required for tuckpointing mortar. It’s crucial that the sand is free from harmful impurities like iron, pyrites, coal particles, lignite, mica shale, alkali, and organic matter, as these can affect the strength and durability of concrete or mortar.

To maintain consistent quality, sand should be protected from seasonal changes. If the silt content exceeds permissible limits, it should be washed using a screw-type sand washing machine. River sand is preferred, but avoid using river sand exposed to tidal water, sea sand, or sand containing white spotted material and shells.

Natural Stones

Natural stones like limestone and sandstone are perfect for creating beautiful edging and retaining walls in your landscaping. They bring character to a structure and break up large areas of the same color.

This material is both fire-resistant and moisture-resistant, which means it doesn’t accumulate moisture. Natural rock and stone have proven their durability by standing strong against various elements for extended periods. When erected correctly, natural rock and stone structures can endure for many years, thanks to their robustness. Unlike some other masonry materials, they are not easily worn down by everyday conditions.

They possess the strength to withstand various conditions, from mild to extreme, including wind, snow, rain, and more. Moreover, they offer a diverse range of colors to choose from, adding to their aesthetic appeal. Maintenance requirements are minimal, and you have a lot of creative freedom when working with natural rock or stone, allowing you to achieve the desired outcome.

While they are highly resistant and durable, they can be somewhat challenging to install. Additionally, they tend to be more expensive than other materials. However, with stone cladding, you can create stone walls without breaking the bank.

Stone Veneer

If you want to bring a natural stone look to your home’s interior or exterior without breaking the bank, consider stone veneer. It’s a manmade material designed to resemble natural stone closely. Stone veneer comes in various shapes and sizes, and to the untrained eye, it can look nearly identical to the real thing.

Marble

Marble has made a niche spot for itself, primarily in the form of marble tiles. You can use marble tiles for your floors, bathroom walls, and kitchen backsplashes. Occasionally, marble is also employed for interior decoration, taking the shape of statues or columns.

Granite

Granite has found its place in the world of masonry, especially as a sought-after countertop material. It boasts resistance to spills and scratches that surpasses many other options. Granite tiles are also a favored choice, particularly for bathroom applications.

Mortar

While not a primary construction material, mortar plays a crucial role in masonry. Mortar is the substance that neatly fits between bricks and cement blocks, holding the masonry units together. Mortar can be made from various materials, including cement, lime, and sand, depending on the application. If you’ve ever watched old cartoons where characters lay bricks and slap down a dark paste before placing the brick, that’s the mortar in action.

Veneer Mortar

Veneer mortar is a specialized type of mortar that contains polymers to help veneer masonry units adhere to vertical surfaces. It can be a bit pricey, so it’s best used for manufactured veneer stones, and it’s wise to mix it sparingly in small batches.

Grout

Grout is a mixture of Portland cement and some sand, and its role is to fill the gaps between masonry units.

Grout is the finishing touch for patios, stone floors, and bathroom tiles. Unlike mortar, grout usually has a smoother finish and appears as if it naturally flows between the stones rather than just holding them together. You can even customize the grout color to add an extra layer of uniqueness to your designs.

Rebar

While not a stone, rebar (reinforcing bars) plays a vital role buried within many concrete projects, making it a common masonry material. These are steel rods incorporated into masonry to reinforce concrete, ensuring its durability in high-traffic areas such as driveways, patios, concrete sidewalks, and foundations.