Almost every house has some sort of insulating structure that is built within it. The reason why homes need insulation is that it creates a balance in the temperature inside, which would make it more comfortable to live in.

If a house doesn’t have insulation and is located at a very hot location, the extreme temperature outside will go through the walls, creating a warm environment that would sometimes even be hotter than the temperature outside. Not only does insulation prevent heat from conducting in walls, but it can also protect the home from cold weather. A house that is too hot or too cold is not a safe place to live in, as it can often result in family members getting sick since human bodies cannot withstand these temperatures.

That is why having insulation in your home is very important, and it is also crucial to know the right levels of insulation your house will need. The measurement of how specific barriers like walls or ceilings can provide insulation is indicated by the R-value.

Understanding the R-Value

The R-value is used to identify how strong or weak barriers are in preventing the conduction of heat. Heat can transfer to materials that are used to build houses, and it will continue going flowing around the house if it is not correctly insulated.

An excellent example to show the conduction of heat is by using a metal stick and placing one end in continuously boiling water. After a minute, if you touch the other end of the rod that is not in the water, you will notice that it is hot; this phenomenon is achieved through the conduction of heat that transfers the warmness to other parts of a material. Like the metal spoon, building materials can conduct and transfer heat, and even our bodies can carry it.

An R-value is essential to know if the insulation material is good to use for your home. If the material has a high R-value, then it means that it is able to resist conductive heat more efficiently.

R-value is often determined not only by the material’s ability to resist heat but also by its thickness. However, having materials that have R-value doesn’t mean that your home will already be comfortable to live in. Once you use these high R-value insulating items excessively, especially the thick ones, then you might have trouble letting out heat in the house, as the warm temperature can sometimes naturally occur within the place. Too much heat trapped inside the house can produce excessive moisture, and this moisture leads to the buildup of molds in walls or ceilings.

Combining insulating materials and applying them properly to have a balanced R-value is essential to create the most optimized temperature in the house.

Commonly Used Insulation Materials

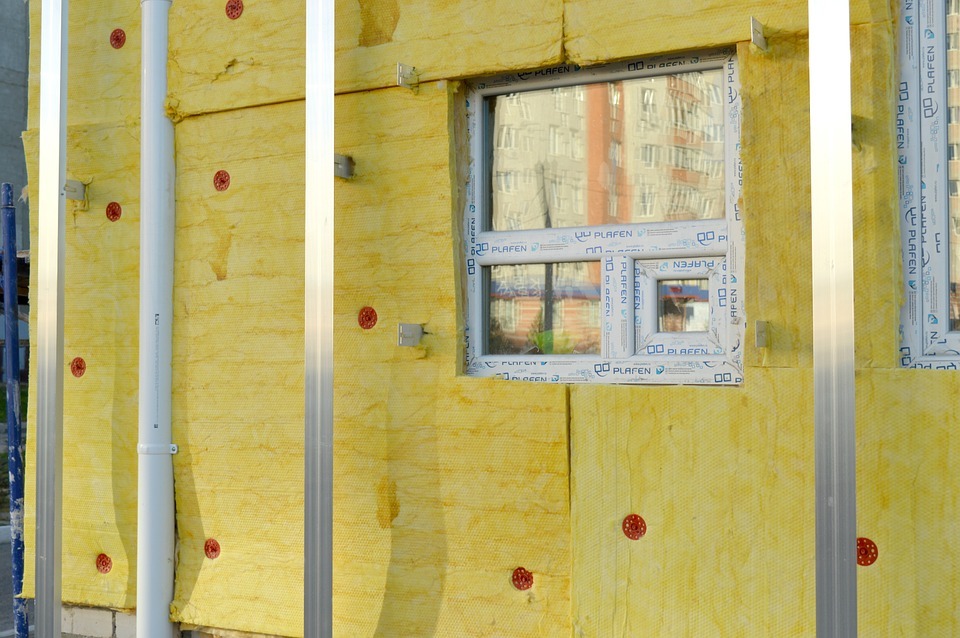

There are many kinds of insulation materials used for building houses and other infrastructures, but some are often more utilized than the others since they can be more effective in resisting heat conduction. Here are a few of the commonly applied insulation materials.

Rigid Panel Insulation

Rigid panels can be used to provide insulation in the inner walls and exterior of a building. This material is typically made out of polyurethane, polystyrene, and polyiso or PIR, which are types of foam plastics. Also, rock and fiberglass are used to create the material to give it a lower R-value.

Polyurethane rigid panels have approximately 7 to 8 R-value per inch, while the ones made out of PIR has 5 to 6 R-value. On the other hand, fiberglass rigid panel offers 2.5 R-value per inch, making it have the lowest R-value out of all types of rigid panels.

Insulated Concrete Form (ICF)

The insulated concrete form is a system of interlocking units that are built in between two concrete insulating walls.

The interlocking units behind the concrete walls are made of durable steel bars that serve as reinforcement to the walls, while the concrete often consists of polystyrene and polyurethane foam materials that can resist heat. The steel bars are dry-stacked, which means that it doesn’t need mortar, a kind of paste used to bind and connect bricks.

Along with its insulating properties, ICFs are utilized to prevent vermin from invading the walls of the house, as the entire structure doesn’t have any closed spaces or tight gaps for parasitic animals to use as their home.

Insulated concrete forms have an R-value of 12 to 17 per inch.

Structural Insulating Panel (SIP)

The structural insulating panel or SIP is similar to the insulated concrete form as it also has a material sandwiched between two boards, but unlike the ICF, the SIP has a solid structure in the middle instead of having interlocking units with gaps, holes, or open spaces within them.

The core or the center of the SIP is normally made of polystyrene and polyurethane foam materials, similar to the ones used for the walls of the ICF. The panels at each side are created using wood, cement, or metal, but the material commonly seen is the oriented strand board, an engineered material consisting of flakes of wood bonded together using adhesives to form a wooden board.

The R-value per inch of SIPs is usually around 13 to 14.

Fiberglass Batts

The fiberglass batt is a material applied to unfinished walls, floors, and ceilings. They are typically used in attics where heat and moisture often get trapped more commonly.

Due to their fragility, fiberglass batts can be difficult to apply, and they sometimes won’t stay in place on their own; those are the reasons why materials that can help support the batts’ weight and allow them to remain in their spots such as staple cloths or wire mesh are needed.

A piece of fiberglass batt has an R-value of 3.1 to 4.3 per inch, and a higher density option for the material has 3.6 to 5 R-value.

Spray Foam

Spray foam is applied using an electric or battery-powered gun and is usually sprayed to seal holes in unfinished walls or newly-installed windows. Due to its sealing ability, spray foams prevents the air outdoors to go inside the home even through the tiniest gaps, which makes it a viable insulating material.

Spray foams are utilized alongside the other materials mentioned above, as the chemical foam is able to fill in the openings or spaces that the larger insulating items create after being applied in a structure.

Currently, there are two types of spray foam found in the market. The first type is made of polyurethane and isocyanurate liquids that combine at the tip of a special gun to create a foam that expands up to 30 to 50 times the volume of the liquid applied. The other type is the cementitious foam, which does not expand and has fire-resisting properties.

Spray foams have an R value of 3.6 to 8.3 per inch. Contact All Seasons Insulation of Los Angeles for professional spray foam insulation and roofing services.

Insulation does not only provide optimized temperature in your home, but it also makes the place energy efficient. By having proper insulation, you wouldn’t have to buy air conditioners or heating systems that could sometimes consume a lot of power or electricity. Before building your dream house, make sure that you know how to plan out and where to get all the basic requirements of having an easeful home, which are insulation, plumbing, and electricity.