You might not be aware that the world of drywall is undergoing a quiet revolution, with innovations that could change how you approach your next renovation project. From fire-resistant panels that enhance safety to laser-guided tools that promise precision cuts every time, the landscape is shifting beneath your feet. These advancements aren’t just for the pros; they’re making waves among DIY enthusiasts keen on tackling projects with newfound efficiency and safety. As dust management and quick-drying compounds enter the scene, the implications for your work environment are profound.

Curious about how these innovations could impact your next project? There’s more to uncover, and the benefits might just surprise you.

Fire-Resistant Materials

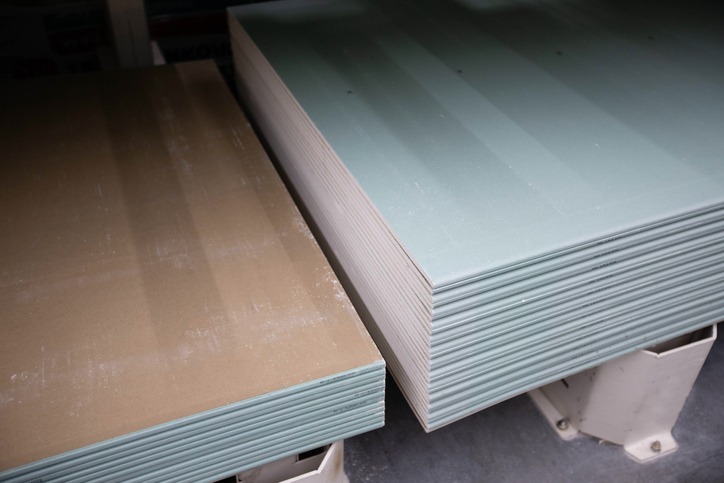

Advancements in fire-resistant materials, such as 1/2-inch gypsum panels, are revolutionizing the safety and efficiency of modern construction practices. This fire-resistant innovation isn’t just about enhancing safety; it’s also streamlining construction with its moisture-resistant panels, which address the scarcity of 1-inch thick shaft liner panels. You’re looking at a game-changer in how buildings are protected from fire threats.

The patented 2½-hour fire-rated system, featuring Type X gypsum panels, is a sign of how far fire-resistant materials have come. With these panels, constructions can meet stringent fire safety regulations without compromising on quality or durability. Plus, the integration of fire-resistant tape solutions further bolsters firestopping capabilities, ensuring that every nook and cranny is shielded against fire.

The MaX 16 pattern by National Gypsum Co. signifies another leap in fire-resistant drywall innovation. This optimized fastener pattern enhances fire resistance, making installations not just safer but also more reliable. It’s clear that these advancements are pivotal in pushing the envelope of what’s possible in constructing safer, more resilient buildings.

Cutting-Edge Tools

While innovations in fire-resistant materials have greatly improved building safety, the development of cutting-edge tools is revolutionizing the efficiency and precision of drywall installation. Among these advancements, a brushless cut-out tool stands out for its precision cutting capabilities. This tool, equipped with the latest technology, guarantees that you can cut drywall with unmatched accuracy and ease.

In addition, the introduction of robot arms in canvas systems has streamlined the mudding and sanding processes, making the finishing steps of drywall installation much more efficient. These robotic assistants reduce the time and effort required, letting you focus on achieving the perfect finish.

Laser-guided cutting tools and automatic taper tools have further enhanced the accuracy and efficiency of work. These advanced drywall tools, with their innovative features, allow for quicker installations while minimizing errors. Ergonomic handles on these tools ensure that you can work for extended periods without discomfort, improving both productivity and work quality.

Among the notable innovations, a dust extractor stands out for its powerful dust extraction capabilities, although we’ll explore dust management technologies separately. Together, these cutting-edge tools are setting new standards in the drywall industry, making your projects faster, cleaner, and more precise.

Dust Management Innovations

Dust management innovations are transforming job sites by capturing over 99% of dust particles, notably improving your work environment and health safety. These advancements don’t just keep your space cleaner; they tackle important health risks associated with poor air quality. By integrating these systems into your workflow, you’re not only enhancing efficiency but also ensuring a healthier working environment.

Here are three key reasons you should consider these innovations for your next project:

- Advanced Dust Extraction Systems: Tools with built-in dust extraction, like laser-guided cutting devices, are revolutionizing drywall work. These systems directly collect dust at the source, significantly reducing airborne particles.

- Cordless Mobile Extractors: The convenience of cordless extractors means you can easily move around the job site without compromising on power or dust management efficiency. Festool’s CTC MIDI exemplifies this, offering robust, portable dust control.

- Low-Dust Compounds and Ergonomic Tools: Using low-dust drywall compounds in conjunction with tools featuring ergonomic handles not only minimizes dust exposure but also reduces worker fatigue. This combination is essential for maintaining high productivity levels on construction projects.

Soundproofing Solutions

In today’s construction and renovation projects, soundproofing solutions like QuietRock 545 are becoming essential for creating quieter, more peaceful environments. With high STC performance, this type of soundproofing drywall is designed to reduce noise in both residential and commercial spaces. Innovations in gypsum-based materials have led to the development of specialty sound attenuation products, focusing on enhancing acoustics and minimizing sound transmission between rooms.

These advancements aren’t just about the materials themselves but also involve the tools and systems that make installation more effective. Flexible cornerbead systems, such as Fast Edge Roll, offer a quick and efficient way to apply soundproofing in corners and edges, where sound can often find a way through. Additionally, drywall suspension systems engineered for sound isolation, like those provided by USG, cater specifically to the acoustic performance needs of ceilings.

Installation Efficiency

Moving beyond soundproofing solutions, the focus now shifts to how advanced drywall tools and techniques enhance installation efficiency. You’re at the forefront of a revolution where the latest innovations in drywall technology not only promise but deliver unmatched efficiency and precision. Let’s explore some of these groundbreaking advancements:

- Cutting-Edge Tools: The introduction of laser-guided cutting tools and automatic taper tools has revolutionized the way drywall is installed. These tools streamline the installation process, ensuring cuts and joints are precise and greatly reducing manual labor.

- Advanced Compounds: Innovative drywall compound formulations with enhanced bonding properties are now available. These new formulations not only improve the installation efficiency but also guarantee a stronger, more durable finish.

- Efficient Cleanup: Cordless mobile dust extractors offer portable solutions for dust extraction. This means cleaner work environments and faster installations, as you no longer have to spend excessive time cleaning up.

In addition, specialized drywall suspension systems and prefabricated drywall soffit framing systems further push the envelope of installation efficiency. These systems, designed for both ease of use and speed, enable professionals and DIYers alike to achieve expert-level finishes in record time. Embrace these innovations, and you’ll find your drywall projects transformed by enhanced efficiency and effectiveness.

Conclusion

To sum up, you’re now equipped with the latest in drywall technology that’s transforming how you tackle projects. From fire-resistant materials that enhance safety to cutting-edge tools that streamline your work, you’ve got it all. Dust management innovations are keeping your space cleaner, while soundproofing solutions offer that much-needed tranquility. And with strategies boosting installation efficiency, you’re saving time and effort. Embrace these advancements; they’re making your drywall work safer, faster, and cleaner than ever before.