Valve actuation is a critical aspect of industrial processes, ensuring the smooth control and regulation of fluid flow. Over time, the field of valve actuation has undergone a remarkable evolution, transitioning from manual systems to sophisticated automated solutions. In this article, we will explore the journey of valve actuation, highlighting the benefits and advancements in automated technologies. Additionally, we will examine the contributions of industry leaders such as Neptronic valve actuators in the realm of valve actuation.

Manual Valve Actuation

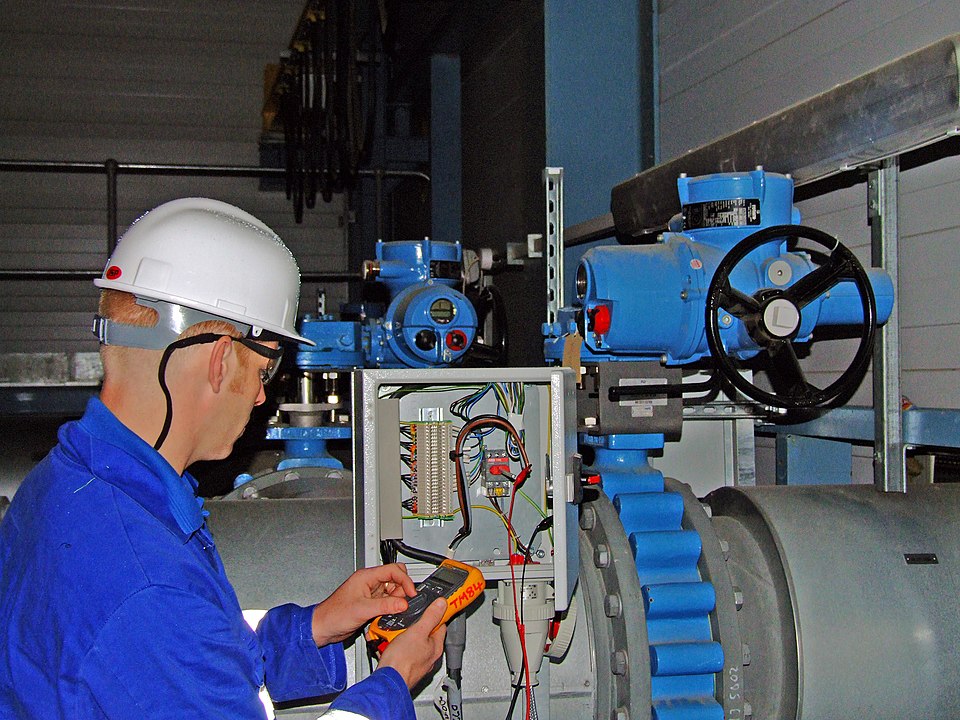

Back in the early days of industrial processes, valves were operated by hand. Workers literally had to turn wheels, pull levers, or crank gears to open and close valves. Just imagine that – someone standing there manually controlling the valves! It definitely provided control over the process, but it was incredibly labor-intensive. And of course, having humans operate the valves made the whole thing prone to mistakes and limitations in precision.

Even with all its drawbacks, manual valve operation still has some uses today. In situations where you need something simple and low-cost, manually actuated valves can make sense. But for the most part, those days of workers sweating over valve wheels are long gone. These days we have all kinds of automated and computer-controlled valve systems that are way more efficient and precise. Still, it’s amazing to think that those manual valves laid the foundation for modern industrial valve operation. The early processes were basic, but you have to start somewhere!

Introduction to Automated Valve Actuation

The introduction of automated valve actuation systems has been a game changer for many industries. These high-tech control systems allow valves to be opened and closed with incredible precision without the need for constant human oversight. Automated actuation has brought numerous benefits compared to manual valve operation.

For starters, automation improves accuracy and control in ways that human operators simply can’t match. The advanced actuator mechanisms can make slight valve adjustments down to the millimeter to optimize flow rates. This level of precision leads to smoother, more efficient process control across an entire industrial system.

Additionally, reducing direct human involvement through automation increases overall safety and reduces the risk of costly errors from manual mistakes. The automated systems operate consistently based on programmed settings without worrying about lapses in judgment or concentration.

Of course, automating valve actuation also saves on labor costs by minimizing the need for hands-on valve operators. And with less human intervention needed, there is less downtime required for shift changes, breaks, etc. The automated valves can keep working around the clock.

Types of Automated Valve Actuators

There are a few different types of automated valve actuators commonly used in industrial applications. Electric actuators are one popular type. They use electric motors to move the valve between open and closed positions. A major benefit of electric actuators is that they allow for precise valve control. They can also be easily integrated into digital control systems. Major manufacturers like Neptronic, Honeywell and Johnson Controls valve actuators make electric actuators suitable for different industries.

Another common type is pneumatic actuators. These ones rely on compressed air to drive the valve operations. Pneumatic actuators are valued for their fast response times and reliability. They also work well in hazardous environments with risk of explosions. You’ll find pneumatic actuators used extensively in the oil/gas, chemical and petrochemical industries.

Hydraulic actuators are a third type used by many companies. They utilize hydraulic fluid to produce the valve motion. Compared to other options, hydraulic actuators can deliver higher forces. This makes them a good fit for applications that need high pressure. They also enable precise valve control capabilities.

Advancements in Automated Valve Actuation

We’ve seen some really cool improvements in automated valve control lately! Companies like Honeywell have come up with smart valve actuators that hook right into digital systems and automation. These new actuators can do all kinds of awesome stuff.

For example, some have wireless communication so you can monitor the valves remotely. That’s handy for checking on things from the comfort of your office. They also have predictive maintenance abilities, so they can let you know if a valve needs repairs before it fails. And some can monitor the condition of the valve over time so you get alerts if anything seems off.

Overall, automated valve tech is getting really intelligent nowadays. The new actuators are like having a talented assistant managing your valves for you! I’m excited to see what other handy features they come up with next. This kind of innovation is making valve control and maintenance smoother than ever.

Benefits of Automated Valve Actuation

Using automated valves can really improve industrial processes. Automated valves open and close more accurately than manual valves, so they give better control over the process. This leads to higher product quality because conditions like temperature and pressure are more precise.

Automated Honeywell valve actuators also have safety features that manual valves lack. They can monitor conditions in real-time and take action if something goes wrong, like shutting off flow if pressure gets too high. This prevents accidents and equipment damage.

With automated valves, workers don’t have to manually operate the valves anymore. This saves labor and lets the process run faster with less stopping and starting for valve adjustments.

The automated valves can send data back to the control system too. This allows for advanced process optimization and analysis when the valve data is combined with other sensor readings. The plant managers can really dial things in to maximize productivity and quality.

Considerations for Implementing Automated Valve Actuation

Installing automated valves like spring return valve actuators can make your operations run more smoothly, but you’ll want to think through how to make them work best for your needs. Here are some tips:

- Look at what exactly you want the valves to do. Will they be able to integrate with your existing equipment and controls? Making sure they fit your specific application will ensure you maximize the benefits.

- Do the math on costs versus potential savings. Automated valves involve an upfront investment, but can pay off in the long run through improved efficiency and reduced labor. Make sure the numbers add up for your business.

- Get your team up to speed. Your maintenance and operations people will need training on how to use and maintain the new valves. Invest in skill-building to ensure they can keep the valves performing optimally.

The Future of Valve Actuation

What’s in store for valve actuation technology? The future looks exciting! New improvements in control systems, the Industrial Internet of Things (IIoT), and data analytics will likely help optimize industrial valve processes even more.

Leading manufacturers like Neptronic, Honeywell, and Johnson Controls seem poised to keep innovating. Their focus areas? Boosting energy efficiency, sustainability, and smart control of valves.

We can expect valve actuation to get ever-more intelligent. Valves will be able to automatically adjust based on data analysis, without human input. This fine-tuned control should increase efficiency across manufacturing sites and other industrial facilities.

The coming years will be fascinating to watch as valve actuation evolves. Companies will find creative ways to integrate emerging technologies and meet customer needs. While the details remain uncertain, one thing seems clear – valve actuation has an innovative future ahead!

Conclusion

The way valves are controlled in industrial settings has really changed over time. Valves used to always be manually opened and closed by workers. Now, valve operation is often automated through advanced computerized systems. This switch from manual to automatic valve control has totally transformed many industrial processes.

With automated valves, operations can be precisely controlled to get optimal results. Safety is also improved because less direct human involvement reduces risks. And as you’d expect, efficiency has gone up thanks to the accurate fine-tuning that automation enables.

Some big players in making this automated valve technology a reality are companies like Neptronic, Honeywell, and Johnson Controls. Their innovations in actuation systems, transmitters, and digital valve controllers have been crucial to advancing automation.

By implementing these intelligent automated valve solutions, industries have been able to take their processes to the next level. Automated control helps reduce costs, optimize processes, and set up plants for even more automation advances down the road. The future of industrial valve operation is definitely an automated one!