The world of manufacturing has never been as competitive as it is today, and time is of the utmost importance. Not to mention, since the CNC metal cutting and precision machines have plenty of settings and options installed in them, they can easily give you a great many opportunities to help you increase your efficiency, including speed. However, before you go ahead and program the CNC machine for quick and fast service, you need to make sure that you have the idea of how much time you want the machine to take on a single piece of work.

CNC productivity is based on various factors. For one, the material of the workpiece is definitely the major part of it and other than that, it is the program and commands that run the machine. Together, both of these factors become of utmost importance in the case of CNC effectiveness and productivity.

If you are looking for a way to increase your CNC machining speed without giving up the quality of the cuts, then this is the guide for you. And for cutting-edge cnc milling, click the link given.

Let’s get started.

1. Get organized

To increase the machining speed, you need to be clear as to what it is that you want to achieve. Your workers need to have the idea of an end goal. Yes, we know that at this point, there would not be any actual work, but by mapping out a plan, you’d get to know exactly how you can make it to the goal at a lesser time. Organize your workforce in such a way that the goal is achievable.

Do you have any complex tasks? Well, simplify them. Not only that, but you also need to train your personnel to do the same, because in the end, every individual step matters. Getting each one of your personnel up-to-date with organized workflows is something that’ll help you shave a lot of time in the long run.

Each shop floor is divided into work cells where individual personnel does their job. It would help if you made sure that each of those work cells is equipped with all the tools that are needed to complete a particular job.

Get ready with all the documents regarding the specifics of the job beforehand. Doing so can easily remove any need for calculations in the later part when you are about to start the work. Keep in mind simplifying the task. You are making it easier for the lower-skilled personnel to do the same job as well, thus increasing the number of hands-on a particular job on a grand scale.

2. Look for choosing Lean Manufacturing Practices.

In the grand scheme of things, lean manufacturing practices can be defined as a method of eliminating waste. But in reality, it is just one part of lean methodology’s core philosophy, which is optimization. One thing that you should know about efficient work is that it usually means shortening the time span of the work while also maintaining the quality of the final product. It wouldn’t be ideal for you to reduce the effort put in if you were to sacrifice the quality.

This is where lean management comes in. Many lean management experts consider this methodology not as a faster means of going a job but instead a way of doing various steps in a parallel fashion, or as someone would say, ‘side-by-side.’

It is one thing to make the people see the waste. However, it is completely different to give them the tools that they can use to produce low waste. As in the previous tip, we told you about planning out the job before working, here we are telling you that you should definitely think about getting the right tools before putting in the effort. And it would help if you also made sure that the tools are in the right condition.

3. Carry your tools to their Limits

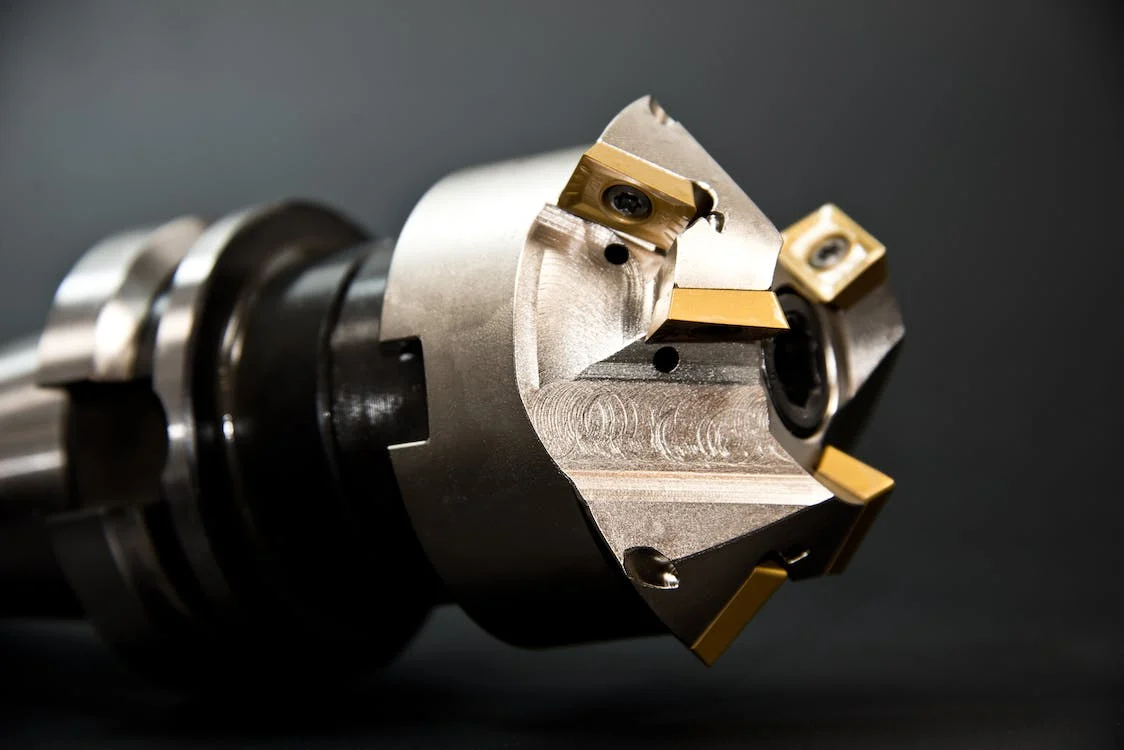

In order to get the best quality products, you need the right tools. Now that you’ve got the right tools, you also have to ensure that your work is fast and the quality is still the same. And that is why you need to push your tools to their limits. The CNC machines of today can handle a lot of workloads, so you can easily push their limits.

Not only that, but the modern CNC machines come equipped with features that increase the removal rate in terms of the tools and the workload. In short, it is easier for your personal to-do these short changes in the middle of their work.

This is one reason why CNC machines are considered to be one of the most profitable assets that a manufacturing brand could buy. However, you also need to understand that if they are idle, they could easily become an overhead expense. It is common knowledge in manufacturing that the chips should always be flying. Since these machines are capable of many things, you can ensure a faster working rate if you use them effectively.

4. Keep the Cycle Time in Check

First of all, let’s get it straight. The cycle time is usually calculated by dividing the amount of machining time by the total number of parts made in that time span. But, in modern CNC machines, you can get access to automated data that is collected throughout the process and is much more accurate.

From data of a cycle time of a single piece, you can actually find out the amount of cycle time that you could say after the whole project. Let’s say you have 15 parts. You make a single part and end up saving 1-minute. So it is clear that by the end of the project, you’ll save over 15-minutes.

Now, let’s take the same example and change the values. Let’s say that you save 4-minutes in making a single part. Thus, it means that you’ll be able to save a whole hour after finishing the project.

From a smaller perspective, the cycle time might appear negligible. But then again, in a broader sense, it can be quite useful.

And on that note, we have finished this article that’ll give you all the information that you needed to increase your machining speed. We hope that you found this quite informative.