Upon ensuring the safe delivery of water, plumbing must not be taken for granted. A pipe is made possible to secure clean water usage; which makes plumbing one of the highly essential matters in human’s daily life. If plumbing is not used for water usage, untreated human waste and fecal matter might be included in our water consumption. With this, pipe holds importance towards water suppliers and users as well.

Commonly, the plumber is accountable for the pipes system which is within a building. The method of pipes transports water to faucets, appliance, and thus, it removes wastes. The plumbers do the installation and maintenance of the plumbing system to secure clean water usage. By plumbing, delivering clean water and eliminating the waste of it is possible. The residue which was not filtered by pipe may cause infectious disease which draws out from the history. In general, plumbing technologies continue to protect many lives within different nations.

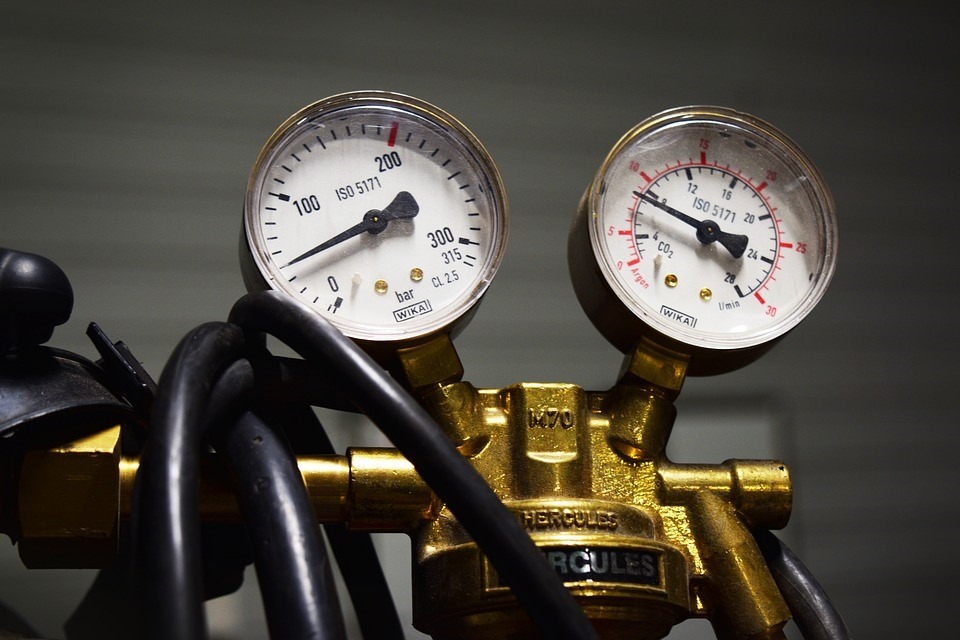

With that, the following are the ways and techniques on how to plumb in a flow meter. And to have stable conditions, using a flow sensor is necessary. Measuring the accurate rate of fluid flow within a system is essential for its totality’s function. It applies equally to liquids and gases – the most integral part of the process. In most cases, the installation of any flow meter is justified and adjusted in two possible ways:

Process Control

The use of flow meter in this way is to measure the rate of fluid or energy flow that allows the process to be controlled and with that, it ensures that the end product is one of the expected and required quality. The most common example for this is the steam injection systems for the animal feeds industry: not sufficient and too much steam, it affects its result; thus, damage the production machinery.

Cost Allocation

In Cost Allocation, energy is used in providing process or space heating. It is because it is essential to determine the costs associated with energy because it is were actuality being incurred. With this, flow metering allows energy costs to be assigned to a specific department, product, or another user which results in a significant reduction in total energy costs.

To understand better the Pipe Flow rate, within the measurement of the flow rate of a fluid that is flowing under pressure is carried out due to various purposes and reasons. It may serve as billing for water supply to homes or business, or for monitoring or process control in a wide variety of industrial processes that are involving the flowing fluids.

Within the pipe flow measurement, it is often finished through a differential pressure flow meter. Just like orifice, venturi meter, and flow nozzle. Each of this type, a constriction in the flow path makes the pressure drop across the meter. Within the pressure drop, it can be measured and correlated with the flow rate.

To help you with how to plumb with these flow meters, the methods of pipe joining, here are the few ways you could use:

Soldered

The process of joining pips wherein melting a filler metal with a low melting point into a joint is done. When the filler metal cools, it joins together the two separated metals. By doing this in plumbing, this method is done with copper piping.

Brazing

It is similar and alike with soldered joints. In this, the metal being joined is used for filling a joint between two base metals. It is done primarily on water piping especially on water services or even diameter tubing.

Threaded

It is related to galvanized water piping. It is a dying joining option. Most commonly, and regularly, it is used for repairs or on specialized fittings example flange fittings. However, this method is not the preferred way of installation.

Fuse seal

It is also known as Polypropylene Piping. It already exists in the year 60s. The fusion technology is used when plastics being joined cannot be merged with the use of the cement. The pipe and fittings are in real fused into one piece along the area of contact to ensure a positive seal.

Mechanical Joint

It is a method in joining piping or fitting by way of a coupling that uses compression of a rubber gasket ensuring a watertight seal. The best examples for this are the flanged pipe fittings and the grooved pipe with coupling or fittings.

Takeaway

To ensure that the service you would give to the people who have entrusted their water supply be clean, you may take the ways as mentioned above to help you with your work. Upon purchasing high-quality material for plumbing, always consider where to buy your equipment. Thus, take on Smart Measurement Flow Meters to fully achieve the performance you could do to secure clean water supply. You may visit and refer for more information within their available website.